Introduction of MP-180 High Pressure Microencapsulation Machine(Microcapsule Embedding Machine)

Key words:Microcapsule forming machine; Microencapsulation Machine ; Microcapsule encapsulation instrument; Particle molding machine; Microcapsule Granulator ; Microcapsule Embedding Machine

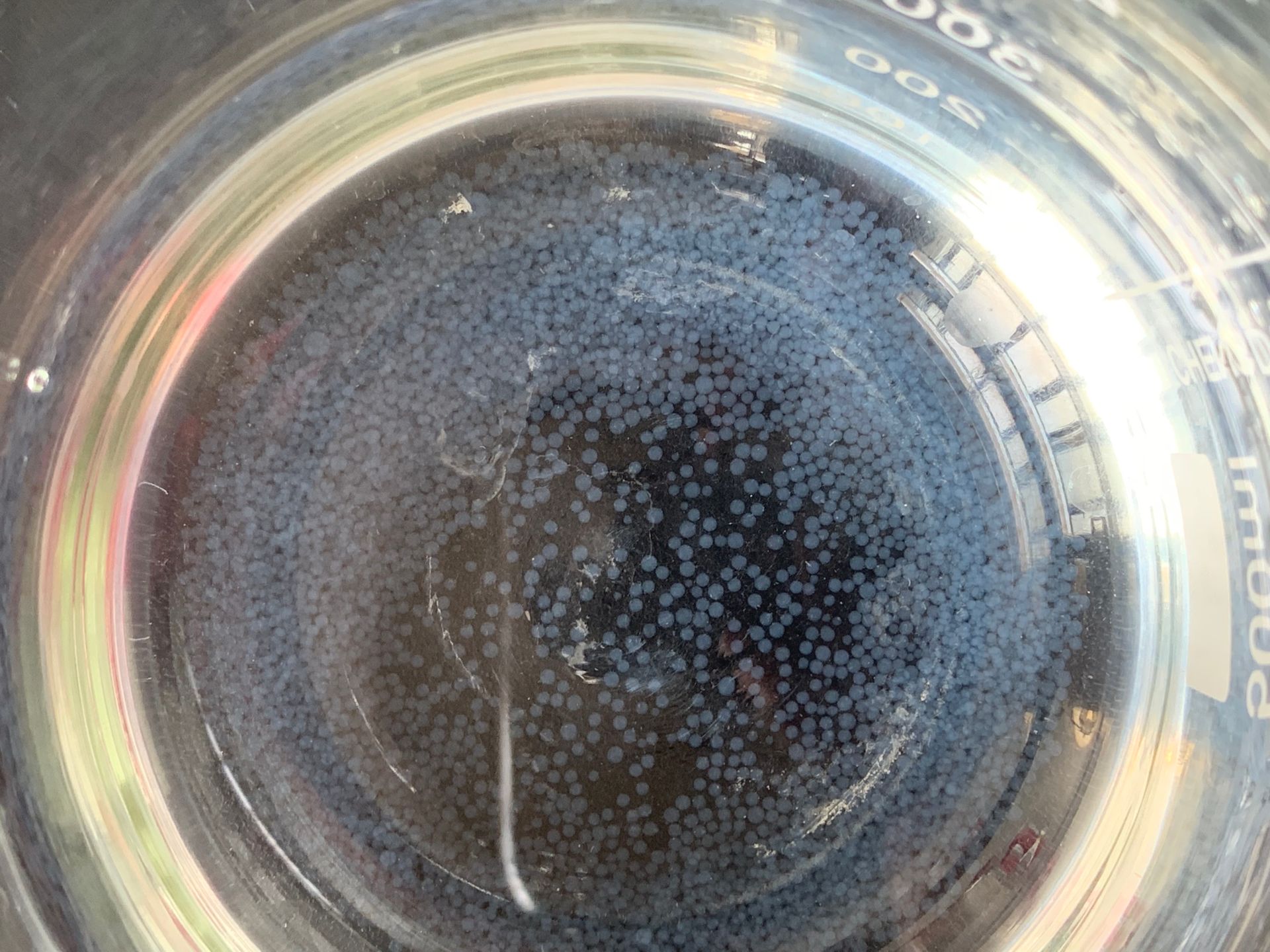

Shanghai BosinTech MP-180 High Pressure Microencapsulation Machine MP-180 has the advantages of simple structure, easy operation, regular spherical shape of the prepared microcapsules, uniform size, smooth surface and high quality, which is widely recognized and applied in pharmaceutical, biotechnology, food, material and cosmetic industries. Various polymer matrices (e.g. alginate, cross-cabbage gum, cellulose sulfuric acid, chitosan, gelatin, pectin or wax, etc.) can be used as wall materials to encapsulate active ingredients (e.g. cells, enzymes, drugs, aromatizers, flavors, vitamins, oils, microorganisms and other active ingredients), thus achieving the purpose of stabilizing and protecting these active ingredients.

ShanghaiBosinTech MP-180-High Pressure Microencapsulation Machine Advantages

Disadvantages of the commonly used microcapsule forming methods: complex coacervation method and airflow atomization method, which have the disadvantages of complex preparation process, poor particle size, uniformity and shape consistency!

ShanghaiBosinTech MP-180 High-Pressure Microencapsulation Machine MP-180 adopts high-voltage electrostatic field technology to overcome the shortcomings of traditional microcapsule molding methods, and has the following new features:

(1) ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine , to prepare microcapsules with uniform size, spherical shape, smooth surface and moderate size;

(2) ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine , with the advantages of compact structure, easy operation, prepared microcapsules of regular spherical shape, uniform size, smooth surface and high quality, can be applied to the needs of preparing microcapsules in biochemical, pharmaceutical, food and other fields;

(3) ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine adopts the principle of high-voltage electrostatic field, and the sample preparation process can be processed at room temperature and low temperature. It is especially suitable for heat-sensitive samples, such as probiotics, cells and other materials.

MP-180 High Pressure Microencapsulation Machine Instrument Parameters

1. Weight: 13.5 kg.

2. Working current: 0-1A adjustable.

3. High voltage electrostatic generator: voltage and current are adjustable.

4. Acrylic syringe: 10 mL, 20 mL.

5. Constant-speed injection device: 9 sections of speed can be set from 20 mm/h to 100 mm/h.

6. Lifting platform: can place beakers and stirrers, and can manually adjust the height (optional).

7. Power supply voltage: input voltage AC220 V, output voltage 0-30 KV continuously adjustable.

8. Syringe: industrial stainless steel needle, injection barrel with standard stainless steel needle holder, can install different tube diameter injection needle.

9. Embedding particle size: 50 μm-200 μm.

MP-180 high pressure Microencapsulation Machine

1. ShanghaiBosinTech MP-180 high-pressure microcapsule encapsulation machine applied in the field of cigarettes: filter stick flavor, popping beads, etc.;

2. ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine applied to the pharmaceutical field: masking odor and color, reducing toxicity, improving processability and stability of substances, extending storage time of volatile substances, and delaying or controlling the release of capsule cores;

3. ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine applied to the food field: probiotics, seasoning products, oil and grease products, probiotics, health care products, food additives, food nutrition fortifiers, enzymes, etc.;

4. ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine applied to the chemical field: flavor and fragrance embedding, cosmetics, etc.;

5. ShanghaiBosinTech MP-180 high-pressure Microencapsulation Machine applied to the field of packaging materials, etc.;

6. ShanghaiBosinTech MP-180 high-pressure microencapsulation machine is used in the medical field, egg cell embedding, etc..

ShanghaiBosinTech Bosin - MP-180-High Pressure Microencapsulation Application Catalog (Excerpt)

1.ShanghaiBosinTech MP-180 high pressure Microencapsulation Machine applied to cigarettes

Abstract: The role of adding flavoring spices to cigarettes is to improve the physical and chemical properties of cigarettes, round out the aroma, modify the flavor of the smoke, improve the taste, establish the style of the product, which in a way affects the consumer's sense of smell, taste and touch, and enhance the acceptability of the product. At present, cigarette aromatization methods include: spraying aroma in the tobacco; adding aroma threads with aroma adhered to the filter stick.

The use of MP-180 microencapsulated cigarette flavoring can make the flavoring softer and more volatile, enhance the retention period and improve the quality of cigarettes.

2.ShanghaiBosinTech MP-180 high pressure Microencapsulation Machine applied to pharmaceuticals

Abstract: Because MP-180 microcapsules have the functions of protecting substances from environmental conditions, masking odor and color, reducing toxicity, improving processability and stability of substances, extending storage time of volatile substances, delaying or controlling the release of capsule cores, isolating unmixable compounds, etc., they are often favored by scientific research institutions and pharmaceutical companies. In product development and production, it is used in such applications as volatile, easily degraded, easily photolyzed secondary metabolites, drugs that require slow release and targeted action.

Abstract: Since MP-180 microcapsules can protect substances from environmental conditions, mask odor and color, reduce toxicity, improve the processability and stability of substances, prolong the storage time of volatile substances, delay or control the growth of volatile substances Functions such as release and isolation of immiscible compounds are often favored by scientific research institutions and pharmaceutical companies. In product development and production, it is used in secondary metabolites that are volatile, degradable, and photodegradable, and drugs that require slow-release and targeted effects.

3. ShanghaiBosinTech MP-180 high pressure microencapsulation machine applied to traditional Chinese medicine

Abstract: Microencapsulation of Chinese medicine by using MP-180 can make the drug achieve a certain slow release effect. The water-soluble core solution is uniformly dispersed in the oil phase by the action of emulsifier to form an emulsion (w/o), while uniformly stirred and dispersed in the sodium alginate solution with the help of sodium alginate suspension, and then it is made into microcapsules by high pressure electrostatic method. Principle of controlled release: Diffusion is the main mechanism of LTH transport. Due to the concentration difference (or osmotic pressure difference) between the drug inside and outside the oil phase, the middle oil phase can be used as a semi-permeable or permeable membrane, so that the drug is slowly transported by diffusion through the oil membrane.

4.ShanghaiBosinTech MP-180 high pressure microencapsulation machine for food and chemical materials

Abstract: With the development of food biotechnology, MP-180 microencapsulation technology is widely used in food research and development, processing and production, and product packaging. The application of microcapsule embedding technology in food includes spray drying, spray condensation, fluidized bed coating / air suspension method, extrusion method, coalescence method / phase separation method, electrostatics method, with the preparation process is complex, particle size, uniformity and shape consistency is poor and other deficiencies, and the MP-180 microcapsule encapsulation machine developed by ShanghaiBosinTech Company uses the high pressure electric field method to overcome the above deficiencies, has the following advantages The MP-180 microcapsule encapsulation machine has the following advantages: it can prepare microcapsules with uniform size, spherical shape, smooth surface and moderate size; long encapsulation time, stable structure, less loss of raw materials for food processing, and improved production yield, etc.

5.ShanghaiBosinTech MP-180 high pressure microencapsulation machine applied to seasoning products

Abstract: The main body of natural spices is volatile aromatic oil, which is highly volatile and easily oxidized, so it is greatly restricted in direct use, so MP-180 microencapsulation is used to increase its use value. The traditional microcapsule forming methods for spices are: compound coalescence method and airflow atomization method, which have complicated preparation process and poor particle size, uniformity and shape consistency. We will extract the volatile oil of spices, using MP-180 microencapsulation technology to make solid seasoning, that is, first make the essential oil to form micron-level oil droplets, and then wrapped by the film-forming substances, isolated from the outside world, can effectively inhibit the volatilization and oxidation of essential oils, compared with the existing seasoning oils, microencapsulated spices have easy to use, not easy to deteriorate, easy to mix with other solid seasonings, such as salt, sugar, monosodium glutamate, etc., and low packaging cost.

返回

返回

tel:021-37656257

tel:021-37656257 email:shbosin@163.com

email:shbosin@163.com  Adds:Shanghai Songjiang industrial district1108 Number

Adds:Shanghai Songjiang industrial district1108 Number  Fax:021-61769285

Fax:021-61769285 Q Q:3152715460

Q Q:3152715460